Waste Tire Recycle Machine/Used Tire Recycling Plant/Scrap Tyre Recycling Equipment

Rim wire welding machine can be design for different machine according to customers' requests, now we introduce two kinds: automatic Double heads type and automatic 8-head type.

Description

Description

Rim wire welding machine can be design for different machine according to customers' requests, now we introduce two kinds: automatic Double heads type and automatic 8-head type.

Main Features

Automatic 8-head type wires welding machine is specially used for welding of baby carriage rim wires, it is a customized automatic welding machine which can complete welding at one time according to the size of customer's workpiece and the number of wires.

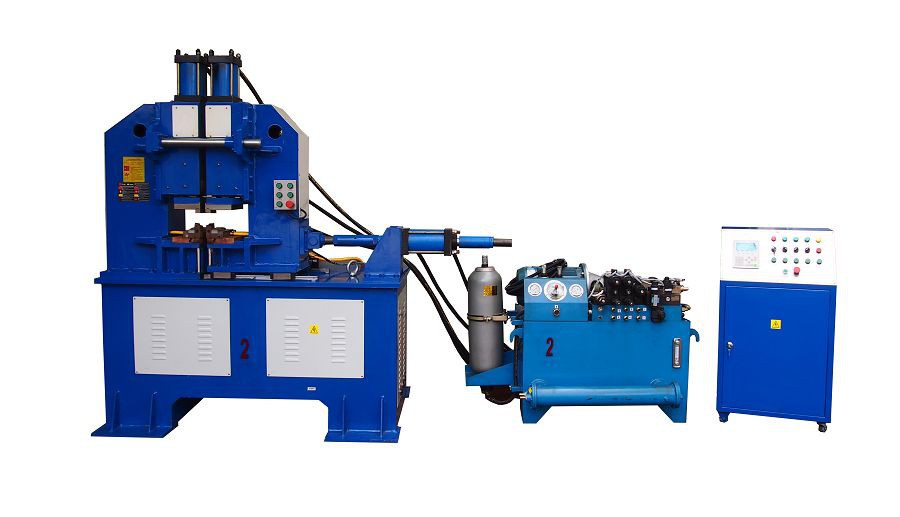

Double Heads Type Wires Welding Machine main use for welding the rim wires, it can weld two wires together, then turn, then welding automatically.

Main Technical Parameters

Model | Rated Power | Rated Voltage | Rated Frequency | Max Short Current | Rated Duty Cycle | Max Clamping Force | Cooling Water Required | Average Weight | Dimensions L*W*H (CM) |

UN-75*2 | 75KVA*2 | 380V | 50/60Hz | 24000A*2 | 50% | 6500N | 150L/H | 550Kg | 150*90*150 |

UN-100*8 | 100KVA*8 | 380V | 50/60Hz | 28000A*8 | 50% | 6500N | 150L/H | 850Kg | 220*90*170 |

Application

1.Various metal wire and steel strip, wheel rims;

2.Widely used for the field of construction, express way, bridge, steel wire drawing plant, cement prefabricated factory, metal products and so on. Especially suitable for using in the construction field and country side.

Guangzhou Dtragon Welding Co.,Limited have Rim Producing Line

Certification

Wheel rim butt welding machine has acquired CE Certification compliance with European Standard EN1004, CCC certification for Chinese high quality standard. our factory also achieved certification with ISO 9001 International Quality Management Standard to evidence and guarantee this projection welding machine offering excellent safe quality & stable performance.

Packing and Delivery

Our wheel rim butt welding machine will be strictly inspected before packing and shipping out to insure that they could be satisfied with you, and our packing box is very strong.

Successful Case

1. Guangzhou Dragon Welding Co. Ltd was one welding machines manufacturer in China.

2. Strong professional technical team and design team ensure to produce welding machines with top quality.

3. Rich experience on manufacture field with more than 20 years export experience.

4. We provide OEM, ODM service, you could let us know all requirements, our design team and technical team will produce them according to your requirements.

5. We provide samples welding service and good after-sales service.

Licenses and Qualify

FAQ

Q1: What does your factory produce ?

A: We produce and export all kinds of automatic welding machine and rim wire welding machine. We also can design and develop the welding machines according to your requirements.

Q2: What about your standard delivery date ?

A: Usually 20-50 days. Our company provide just-in-time delivery

Q3: Do you sale welding electrodes ?

A: YES, you can buy welding electrodes from our factory or in your local market.

Q4: Do you have CE Certificate?

A: YES, we have.

Q5: Can you export machines by your factory?

A: YES, we can.

Q6: Where are your factory?

A: Our factory located in Guangzhou City, Guangdong Province, China.

We will provide same good after-sale service as the pre-sale service, any of your questions, we will be replied within 12 hours.

Hot Tags: rim wire welding machine, China, manufacturers, suppliers, factory, price, induction heater for straightening wires, wire shelf space saving shelf, welding presentations, welding environment, welding for assemblies by spot welding, flash butt welding productivity

Send Inquiry

You Might Also Like